Our last few blog posts have looked at the challenges facing owners/operators of industrial plants – increasing reuse of process water, as well as better management and reduction of effluent discharge.

Use, Recover and Use Again – Industrial Wastewater Reuse is The Name of The Game

Water is a precious commodity that was once available almost free of cost, especially for industrial use. This is no longer the case. Water is no longer free for people or for industry and has, in fact, become so costly and/or scarce for industry that it is now considered the same as any other raw material.

Water is used for multiple purposes in all types of industries, and the vast majority ends up as industrial wastewater. The release of this wastewater back into the environment creates a significant footprint, and discharge regulations are becoming ever more stringent. It is of paramount importance that we make every effort to reduce the use of purchased water and/or water from natural sources, and treat wastewater to make it reusable or, at least, safer to discharge into the environment.

What is Industrial Wastewater Reuse and Recycling?

Whether you call it reuse, reclamation, or recycling, it all comes down to the same thing – using water more than once.

When talking about industrial water reuse, there is often a slight differentiation between reusing and recycling – reuse is the process by which wastewater produced from one source is treated to be reused in the same process, and recycled is the process by which the wastewater is treated to be recycled for another process. For many industries, the costs of new water and the regulations regarding the disposal of wastewater, are the main incentives driving the search for effective and efficient reuse technologies.

Is Water Reuse a New Concept?

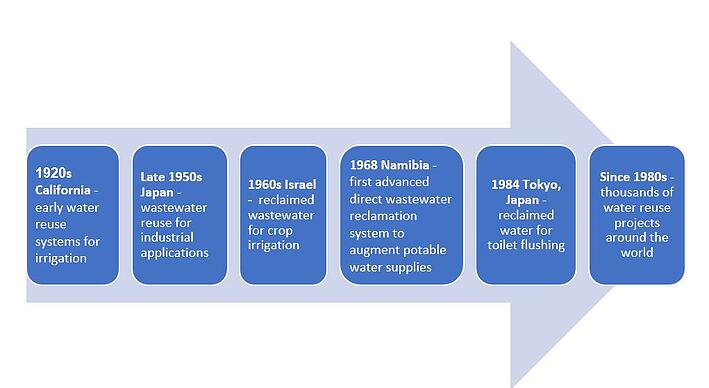

Not really – The practice of recycling previously used water goes back a few years – some say as far back as the early Bronze age (3000 BC), when there is evidence of agricultural irrigation using wastewater in Crete and Greece (Water Reuse Europe).

<< Check out our latest webinar and learn how it can benefit your business >>

So Why the Hype and Buzz About Reuse Now?

There is no argument about the challenge to, and depletion of, global water resources – it is universally acknowledged and well documented. Growing populations, increasing urbanization, and climate change are key factors contributing to this challenge. Adding to already challenged resources, the 20th century saw a major transformation in the world, with remarkable changes in materials, industrial operations, and computerized processes.

This industrialization has resulted in significant improvements in lifestyle for people, around the globe and on many levels, with individuals’ water footprints increasing, and industry requirements growing. The flip side of this rosy picture is the increased risks to the population and the environment as a result. We see this in the form of air, water, and soil pollution that demands remedial measures to avoid irreversible consequences. Add to this the headache of meeting regulations for discharge of waste, and things become even more complicated.

In short, the pressure is on to relieve the stress on natural resources, as well as to reduce operational costs in industry. As water for industrial applications becomes less easily accessible, industry must look for ways to recycle and reuse treated water.

Industrial Reuse

Traditional industrial wastewater disposal methods can be both expensive and less environmentally friendly since they often fail to minimize the amount of effluent for disposal. Innovative industrial water treatment technologies make it economically feasible to convert different types of wastewater back into a purified, reusable state, making this water a valuable asset again, rather than a potential financial and environmental liability.

Disposal of industrial wastewater from an industrial plant is a complex and costly problem. Some of the options for disposal are:

Wastewater Treatment Plant

Wastewater Treatment Plant

Evaporation Ponds

Evaporation Ponds

Surface Discharge

Surface Discharge

Disposal by injection to deep wells is an option, where such wells exist.

These are, however, costly solutions without any added value to plant operation. Thus, it is important, as much as possible, to

- recycle and increase reuse of the water back into the process, and

- minimize the effluents for disposal

And it goes without saying, that where ZLD technology can be implemented, this is the clear winner in terms of the reuse potential, as well as overcoming disposal challenges and reducing costs. Reusing and minimizing effluents will result in a sustainable mode of operation for the plant that is more efficient in the use of water. However, ZLD can be very costly when talking about treating industrial effluents. Innovative thinking is called for when designing the ZLD system, in order for this to be economically viable.

From Vision to Reality

All good in theory you might say, but how do we set about implementing these reuse strategies and technologies?

Every industry should have a person responsible for wastewater reuse strategies, who should consider the following key issues (Industrial Wastewater Treatment, Recycling, and Reuse):

- Can we avoid liquid discharge?

- (Aspire to zero liquid discharge)

- Can we reuse treated water?

- (At least as cooling water or boiler makeup if not as process water)

- How do we manage process economics (In terms of money and space)?

- Where is the dedicated space for the process plant?

- Treatment cost: ~USD X/liter

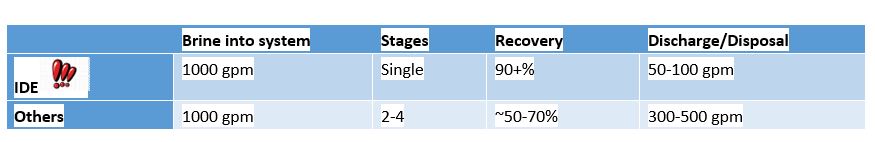

Partner with IDE Water Technologies in your quest for efficient and cost-effective industrial wastewater reuse technologies – you ask the questions; we will provide the answers! We offer a range of solutions for treating and reusing industrial effluents, reducing discharge, reducing costs, and increasing recovery.

Full ZLD

Implement one of our MAXH2O solutions for ZLD:

Membrane Solutions

IDE Water Technologies membrane-based solutions for industrial wastewater treatment overcome the limits of the challenging water chemistry of this effluent, thus providing added value to the client in the form of:

- Substantially lower disposal costs

- Recovery of additional clean water for reuse

- Smaller thermal system resulting in lower Capex and Opex

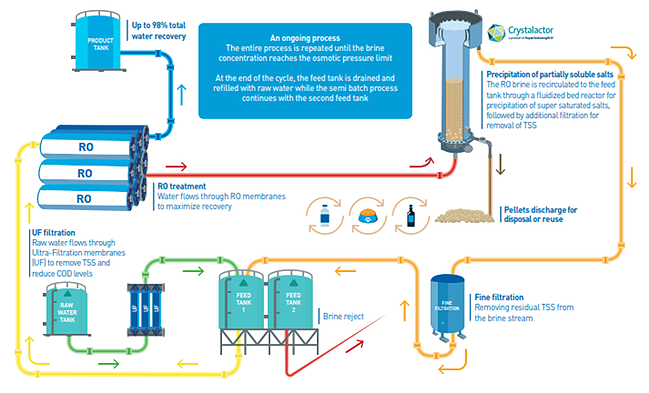

MAXH2O Desalter Solution

A unique process that combines well-established membrane technology with an integrated salt precipitation unit that overcomes the challenges and disadvantages of each technology, respectively. The MAXH2O Desalter overcomes variable changes in the feed flow and composition, while operating at very high recovery without compromising membrane service life, and pushing the limits of calcium carbonate, calcium sulfate, and silica precipitation.

MaxH2O Desalter – a Bird’s Eye View

MaxH2O Desalter – a Bird’s Eye View

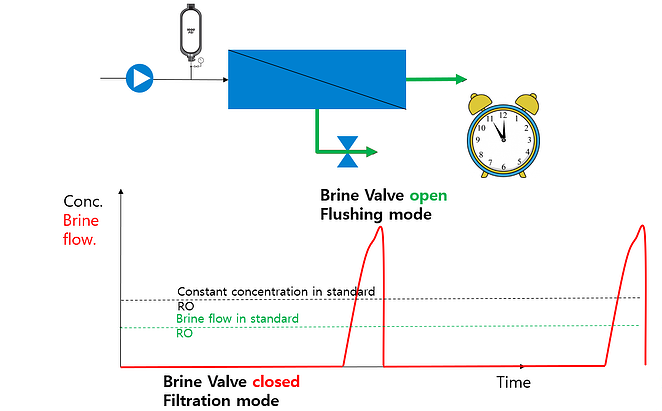

MAXH2O Pulse Flow RO (PFRO) Solution

Contrary to the standard multistage RO structure, Pulse Flow RO technology (PFRO) discharges the brine flow periodically, in a pulse flow process – a small volume of brine flow is discharged at high velocity for a short time. Crystal formation is not immediate. In order for crystals to form, a certain period of time – the induction time – is required at supersaturated and stable conditions. Due to its intermittent flow and changing concentrations, PFRO prevents the existence of these conditions.

MaxH2O Pulse Flow RO (PFRO) Solution

MaxH2O Pulse Flow RO (PFRO) Solution

Both MAXH2O solutions have been extensively and successfully tested – read more about them here.

Let’s Recap

- Industrial effluents are many and varied, with each industry facing its own specific challenges.

- Standard RO systems might not be able to maximize recovery due to the challenges of the complex water chemistry of these effluents

But all is not lost!

- IDE offers unique MLD/ZLD solutions that overcome these challenges

- MAXH2O Desalter – allows the RO to overcome the limiting factor of water chemistry and reach the osmotic pressure limit

- MAXH2O PFRO – pushes the boundaries of RO recovery beyond the saturation limits the salts

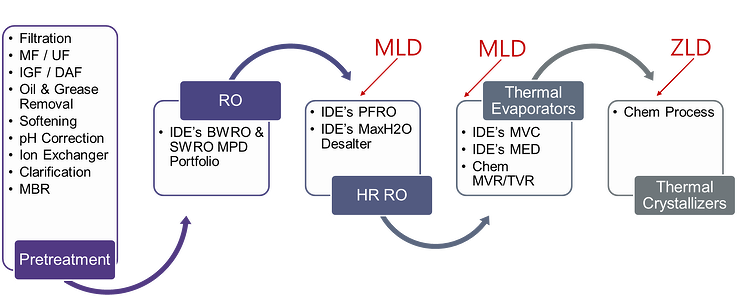

IDE Water Technologies MAXH2O technologies are part of a holistic solution – all the way from pretreatment to ZLD

We have been treating water for more than half a century! We fully understand both the chemistry and treatment of wastewater. Our tailored industrial wastewater treatment solutions have been implemented worldwide, and some have been operating for decades. Our solutions help many industries including mining, power, petrochem, chemicals, data centers, microelectronics, semiconductors, and refineries, tackle and overcome their wastewater treatment challenges. Contact us today to reduce tomorrow’s costs and preserve the planet for our children by reusing your industrial effluents.