Solving The World’s Greatest Water Challenge With Ingenuity And Mathematics

What is the DNA of innovation? Certainly not formal education and advanced degrees. In my opinion, people who have innovators’ brains somehow maintain a childish way of thinking; they simply cannot accept the standard solution for a problem, and they continue to look for other solutions.

But when trying to solve large-scale problems such as the “Pressure Centre” approach, a spirit of innovation is not always enough. Implementing a brilliant idea that cannot be tested on small scale is a scary scenario that can end up dragging the innovator and other people’s money down the drain*. That’s when mathematics comes in handy. When you can back up an innovative idea with mathematical calculations, you hit the jackpot and you have proof (and peace of mind) knowing that even the most out-of-the-box ideas can be implemented successfully.

A spirit of innovation and mathematical models were also the magic formula that helped us at IDE build what was known in 2005 as the world’s largest desalination plant.

*Pressure Centres cannot be tested in lab size, it only can be evaluated in mathematical models).

Harnessing Innovation to Set Up a New Benchmark for Low-Cost Desalinated Water

In the late 90s, water scarcity in Israel was the talk of the town. The water level at the country’s primary natural reservoir, the Sea of Galilee, dropped alarmingly and was announced with a grim tone every evening at the opening of the 8 pm news.

In 2000, the government greenlighted the National Desalination Master Plan to help address the country’s chronic water resource problems. Ashkelon RO Desalination Plant was the first stop in this massive plan with an ambitious goal to provide 100 million m3/day and supply 15 percent of Israel’s household water needs.

Several large companies submitted their proposals for the tender, yet IDE, a relatively small company with a good track record in thermal desalination but little experience in building reverse osmosis desalination plants, won the tender. How come? Simple, the BOT tender was structured around the cost of water, and by introducing three different innovations (yet untested!), we were able to offer the lowest cost of water. In the water industry, the cost of water is the holy grail….always!

Reverse Osmosis Innovation From the Ground Up

The three technologies which allowed IDE to set a new benchmark for the low cost of desalinated water were the Proprietary Pressure Centre Design, a unique arrangement of Energy Recovery System, and patented Boron Removal System for increased efficiency and significantly reduced water costs.

The Pressure Centre design involved a drastic shift from the traditional 32 high-pressure small pumps to a pumping center composed of 3+1 large high-pressure (HP) pumps, 5.5 MW each. The pressure center design increases the system’s availability and reliability and reduces energy consumption due to the efficiency of large high-pressure pumps and the arrangement of energy recovery DWEER as a block that served all RO trains.

Pipe inauguration, the Ashkelon desalination plant.

Pipe inauguration, the Ashkelon desalination plant.

Chasing Energy Recovery Innovation in the Caribbean

Sometimes being innovative is simply about recognizing when something is brilliant and adopting it. Such was the case with the second innovation we implemented in the Ashkelon desalination plant. A very smart person named Bill Andrews built an energy recovery system, DWEER, in a small desalination plant (about 100 m3/hour) in the Caribbean. In a paper he published about this project, he claimed 98% energy recovery. The market standard at the time was 80-85% recovery (Pelton Turbine)!

I took a flight to the Caribbean, visited the plant, saw that it was working, and immediately understood it had a huge potential. When I told Bill I’d like to use his innovation in the Ashkelon plant and process 100 million m3/day, he thought I was joking. I wasn’t. When I went to the tender, I used his innovation and combined it with our pressure center design. Without this piece of the puzzle, we could not have reached the wining cost of water.

A Technological Breakthrough in Boron Removal

The eventual cost of the drinkable water was also impacted by the Israeli government’s demand for as low boron content as possible (0.3ppm). Accordingly, achieving a high boron ion reduction was an important design consideration. But at that time, no one was able to deliver it. We did. We developed a process that transfers water for a second time through a membrane cascade that removes boron ions to concentrations below 0.3ppm. We were able to meet the requirements imposed by the Israeli Water Desalination Authority (WDA), make the water suitable for agricultural needs, and get the innovation patented.

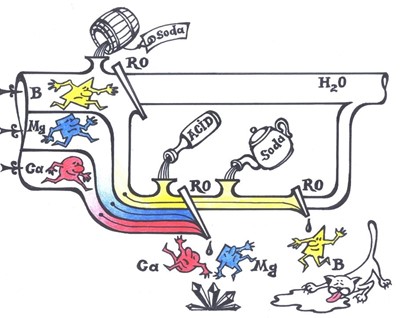

Illustration: Boron removal system

Illustration: Boron removal system

Three Untested Technologies – What’s Next?

When we applied to the government tender, we submitted a plant design that was based on these three innovations that were never tested on a pilot scale. And yet, the commissioning procedure was simple and fast due to the comprehensive mathematical modeling system performed on the entire desalination plant during the design stage.

Our team of four process engineers developed 14 mathematical models. These models reflected, without exception, all the chemical and technological features of the desalination plant. No one at IDE had an idea what we were doing, but they put their trust in us during the two years of mathematical calculations. These mathematical models allowed us to win the tender but, more importantly, be sure that the project would succeed.

Submerging the suction head using a float tank, the Ashkelon desalination plant.

Submerging the suction head using a float tank, the Ashkelon desalination plant.

When the work started, our small team built the entire RO process from scratch, implementing the innovations we developed and crafting a fully automated desalination process that, on Saturdays, could be operated with only two people on board, and even those two were usually busy doing other things; one was making coffee while the other one drinking it…

Powered by innovation and mathematics, the thousand-piece technological puzzle formed a completely flawless picture – no small achievement in a desalination plant the size of the Ashkelon project.

Ashkelon Desalination Plant, 2005

Ashkelon Desalination Plant, 2005

With more than half a century of desalination and water treatment experience, IDE can certainly offer efficient and cost-effective solutions to treat the water and wastewater streams in the power plant. We provide advanced water treatment schemes that “talk to one another,” from the ultrapure water required for boiler feedwater through cooling tower makeup and all the way to the complex cooling tower blowdown stream. Whether you need primary filtration or more robust pretreatment, RO, and a polishing stage of MBR or EDI, we offer holistic end-to-end solutions that maximize your plant efficiency while meeting all regulatory requirements.

The Ashkelon Model Goes Global

The success of the Ashkelon plant, which in 2006 won GWI’s “Desalination Plant of The Year” award, spread across the ocean all the way to Southern California.

At the time, drought-ridden Sun Diego was importing most of its drinking water from Northern California and the Colorado River, and water availability was very limited. The county water authority embarked on long-term water planning and was on a mission to diversify its water supply portfolio.

The Carlsbad desalination plant was the result of a water purchase agreement between the San Diego Water Authority and the Poseidon Group. The Poseidon Group, which was looking for a partner to design and operate the plant, visited the Ashkelon facility, went through all the mathematical calculations, and finally allowed us, a foreign company, to participate in the tender. Once again, due to our bag full of innovative technologies (which by now had real proof of concept), we were able to commit to the lowest water cost and win the tender.

Five years later, the Carlsbad Desalination plant produced 54M gallons (204,412 m3) per day, which represented 10% of San Diego County’s water supply and provided a drought-proof, reliable source of water for local businesses for generations to come.

Water Insecurity is Not Our Destiny

Water scarcity is no longer the plight of places such as Israel and San Diego. As weather patterns change around the world, it has become a global issue that demands the attention of (almost) any water authority and government across the world.

Ashkelon and Carlsbad are only two examples of successful RO seawater desalination plants which were designed and operated by IDE in the past 60 years. In my (almost) thirty years in the company, I was involved with dozens of innovations and technological breakthroughs and more than 60 patents that have increased processes’ efficiency, economy, and reliability, reduced CAPEX and OPEX costs, and environmental impact.

Millions of people around the world face water insecurity. It’s a big problem and, as such, requires a bold solution. I am proud to be part of a company that, for over six decades, is infusing ingenuity and mathematics to solve the world’s greatest water challenges and bring water stability to so many communities around the planet.